|

|

Dowell Materials >

Chang Chun PBT > What is PBT?

|

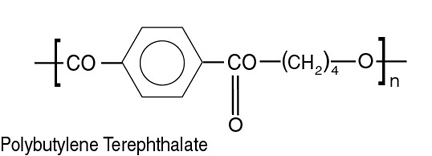

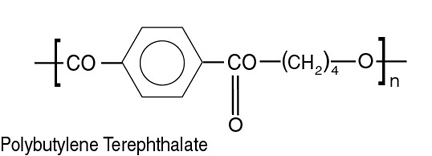

- POLYBUTYLENE

TEREPHTHALATE (PBT)

|

|

Introduction

PBT - Polybutylene Terephthalate is the

synthetic thermosplastic compound of 1-4-Butylene glycol with DMT or PTA.

It was widely used in electronic, electrical, communications, fiber optics

and automotive industires.

There are two kind of PBT product - PBT Resin and

PBT compound.

PBT Resin is the base resin while PBT

compound are combination of PBT resin, fiber glass filling and other

additives such as UV protection agent, and flame retardant.

|

|

Characteristic

-

fast crystallization,

easy to mold.

-

melting temperature

reaches to 225oC, high deflection temperation.

-

fiber glass re-enforced,

good mechanical strength

-

low water absorption

rate, low shrinkage rate

-

resistant to chemical,

solvent and natural weather

-

low warpage

-

can reach UL94V-0

flammability

-

ultrasound welding

capability

-

Good electrical

resistance

-

Fire

retardant being used in CCP PBT does not contain PBDE & PBB Brominated

ingredient.

Example: Chang

Chun PBT molding compound.

| General Specifications

of PBT molding compound |

| Properties |

Unit |

|

| Flexural strength |

MPa |

74.1 ~ 227.24 |

| Tensile Elongation |

% |

4 ~ 9 |

| Tensile Strength |

MPa |

49.4 ~ 138.3 |

| Impact, Izod |

kg-cm/cm |

2.5 ~ 13 |

| Deflection Temp. |

oC |

165 ~ 220 |

| UL Flammability |

mm |

UL94V-0 |

| Water absorption |

% |

0.03 ~ 0.05 |

| Molded Shrinkage |

% |

0.2 ~ 2.0 |

| Specific Gravity |

|

1.32 ~1.66 |

| Glass Fiber Content |

% |

0 ~ 40 |

| For reference

only

PBT reference chart

|

|

Purpose of PBT Resin

- PBT Fiber

- Optical Cable Coatings

- PBT film

- PBT Master Batch

- Glass-Fiber Reinforced & Flame

Retardant Grade PBT Compound

- Electronic Parts, Electrical Parts, and

Auto Parts

Purpose of PBT Molding

Compound

- Automotive accessories,

motor cover, motor brush

- Connectors, cooler fan,

plugs, bobbins, switches

- TV set accessories,

commutators

|

|

Helpful Links

In order to let

you have clear picture of CCP's PBT capability, you can go to the PBT

Reference Chart with other

manufacturers in the world for

reference.

Molding

Conditions for PBT provides you and your engineers the starting

point for machine adjustment.

|

|

|

| Back To Top |

|

|

|

|

![]()